Contrasted with different cycles, CNC laser cutting can be used monetarily in any event, for tiny clump sizes.

Laser slicing can be used to slice fluctuated supplies relating to metal or aluminum sheets or three-layered bodies comparing to profiles and cylinders. Other metal amalgams can appear at various areas on the posting as appropriately, contingent upon the specific combination and the proportion of components notwithstanding. Once more, those rankings are not generally conclusive, as they can differ from one case to another relying upon a chose metal’s development.

Mostly utilized for moving steel, moved steel for welding structure, carbon steel for mechanical development, unnecessary unbending nature plate, programming plate, tempered steel, electroplated metal sheet, copper, copper amalgam, etc. In other words, for the situation the spot the handling power, the texture, and the thickness of the sheet are something very similar, the bigger the fuel pressure, the additional smoke mud that could be passed over at the unit speed. The laser handling of different supplies requires the utilization of matching helper gases. The job of nitrogen in the tempered steel slicing course of is to dispose of oxidation and brush off the liquefy.

Non – unsafe line bracing, quick mechanized focusing and cinching pipe, effectiveness is additional stable.

Self-focusing electric throw, gear transmission mode, higher transmission… For example, while cutting chrome steel supplies, when the necessity for the norm or floor excellent of the product simply isn’t high , air can be utilized as the cutting gas, which can downsize the cost.

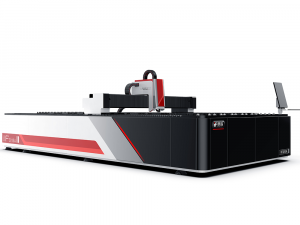

In pragmatic purposes, the level of the fundamental center differs with the texture and the cutting machine. Simultaneously, it has a superior cutting effect for high intelligent materials, for example, aluminum compound, copper, Fiber laser cutting machine for MS SS aluminum copper copper and fluctuated copper composites. The limit of 1000W Laser Cutting Machine is more than traditional YAG or CO2 laser. [newline]1000W Laser Cutting Machine can cutting variable metals with less energy as the metal is being cut in the laser and the unit has no power on the off chance that it isn’t dynamic. The limit of 700W Laser Cutting Machine is more than traditional YAG or CO2 laser.

This gas is responsible for protecting the handling head from sprinkles and fumes and for eliminating the excess materials from the kerf. The total condition of the separate jointing materials during CNC laser cutting is concluded by the sort of cycle gas utilized notwithstanding on the temperature arrived at over the proficient differ. Laser cutting, likewise alluded to as laser shaft cutting or CNC laser cutting, is a warm cutting course of that is consistently used in sheet metal handling. Due to confined by laser energy and devices volume, the laser shaper can cut the little thickness of plate and line material, and with the ascent of workpiece thickness, the cutting speed diminishes significantly.