The ProCutter head not exclusively has all perform of handbook sorts, however also make auto center inside speedy time.

Several sensor inside make quick input all through cutting course of. Ensure the cutting effectiveness for 10kw stage laser cutting machine. The laser power could be picked as per the cutting materials and thickness. Contrasted and plasma, fiber laser cutting machine is more power-saving and productive.

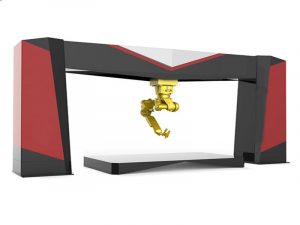

Adaptable and quick, no impact, programmed edge finding, decreasing sheet squander. The welded, sent off and machined bedding, weighing 4,500 kg, is solid and sans vibration, which is fundamental inside the laser cutting course of. Normally, the bed is sent off and machined sooner than joining the huge sq. direct bearing aides.

60-100times contrasted and the processing machine and CNC machine. Particularly reasonable for cutting or etching on Acrylic, Bamboo, MDF, Compressed wood, Expressions Specialties, Hello Cards, Dress, Logo, Bottons, etc. The lightweight scaffold guarantees right cutting results considerably under high-powerful pivot activities. The machine includes totally shut lodge and offers protected and ergonomic operation.The huge eye-safe windows license an ideal outline of the whole working region of the machine.

The frog skip the executives is redesigned with smoothier development and zero respite. With SM 5.0, thin plate producing effectivity can be worked on by more than 25%. The framework can give auto gas shut-off during quick moving and additional helpful auto edge identification.

Han’s Yueming pioneers the reception of CCD Falcon Eye ID ability in China, permitting speedy situating.

Moreover, second cutting is likewise accessible, which assists with understanding a superior cutting effect and higher piece cutting. As per the principles of ergonomics, our laser cutting machine is furnished with a keen activity terminal, whose functional board is 4020 fiber laser cutting machine plainly shown, permitting a basic activity. Reasonable for a great many central lengths, the fundamental objective position could be changed as per various thicknesses.

New sheets get speedier in and remove sheets get quicker of the machine. The total bar is handled by T6 warmth treatment course of to cause the bar to acquire the absolute best strength. Arrangement treatment works on the energy and versatility of the shaft, streamlines and diminishes its weight, and hurries the movement. The machine is placed in by Rensi engineers alongside the client. The client’s most important materials are tried and essential cutting qualities are consummated. The Rensi installer as of now knows about CypCut/HypCut control and programming program (auto settling, settling, screen making, flycut, etc.).

The sleeping cushion build and bar are handled by very good quality CNC gantry processing. The CNC gantry processing is 12 meter machine, eight meter machine and 5 meter machine individually. The supporting offices are full, the apparatuses accuracy is heavenly, the mass handling and creation are high. The gantry is made to flying norms and squeezed in its shape on a 4,300-ton bite the dust projecting machine.