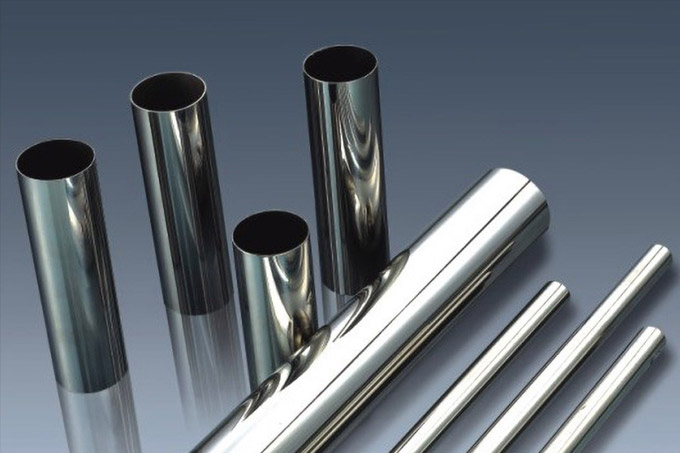

Rolled and welded steel pipe is a versatile and durable solution that finds applications in various industries. Whether you’re involved in construction, infrastructure, oil and gas, or other sectors, rolled and welded steel pipe offers reliable performance and structural integrity. In this article, we will explore the benefits and applications of rolled and welded steel pipe. From its manufacturing process to its wide range of uses, discover why choosing high-quality rolled and welded steel pipe is essential for your industry needs.

What is a Rolled and Welded Steel Pipe?

Rolled and welded steel pipe refers to a type of pipe made by rolling and welding flat steel plates or sheets. The process involves forming the steel into a cylindrical shape and welding the edges together. This manufacturing technique produces seamless and durable pipes that are capable of withstanding high pressure, heavy loads, and extreme environmental conditions.

Advantages of Rolled and Welded Steel Pipe

- Strength and Structural Integrity:

Rolled and welded steel pipe offers excellent strength and structural integrity. It can withstand high-pressure applications, making it suitable for transporting fluids, gases, and other materials. The welded seams provide enhanced strength and prevent leakage, ensuring efficient and reliable operations. - Versatility and Customization:

Rolled and welded steel pipe is highly versatile and can be customized to meet specific project requirements. It is available in various sizes, thicknesses, and diameters to accommodate different applications. This flexibility allows for seamless integration into diverse industries and projects. - Cost-Effective Solution:

Rolled and welded steel pipe provides a cost-effective solution for various industries. Its durability and longevity reduce maintenance and replacement costs over time. Additionally, the availability of customized options ensures optimal efficiency and cost-effectiveness for specific project needs. - Wide Range of Applications:

Rolled and welded steel pipe finds applications in numerous industries. It is commonly used in oil and gas pipelines, water distribution systems, structural supports, piling, and more. The versatility and reliability of rolled and welded steel pipe make it an indispensable component across different sectors.

Applications of Rolled and Welded Steel Pipe

- Oil and Gas Industry:

Rolled and welded steel pipe is extensively used in the oil and gas industry for the transportation of petroleum products, natural gas, and other fluids. Its strength, durability, and resistance to corrosion make it an ideal choice for pipeline systems. - Construction and Infrastructure:

Rolled and welded steel pipe plays a crucial role in construction and infrastructure projects. It is utilized in the construction of buildings, bridges, tunnels, and other structures. The versatility and customizable nature of rolled and welded steel pipe make it a preferred choice for various applications. - Water and Wastewater Systems:

Rolled and welded steel pipe is commonly employed in water distribution systems and wastewater treatment plants. It ensures the efficient and reliable transportation of water and sewage, withstanding the demanding conditions of these systems.

Conclusion:

Rolled and welded steel pipe offers a reliable and versatile solution for industries requiring strength, durability, and structural integrity. With its customizable options, cost-effectiveness, and wide range of applications, rolled and welded steel pipe is an essential component in various sectors. Whether you’re in the oil and gas industry, construction, or water distribution, choosing high-quality rolled and welded steel pipe ensures reliable and efficient operations. Invest in top-tier rolled and welded steel pipe to meet your industry needs and experience the benefits it brings to your projects.