The cake breaker in a filter press is primarily used to facilitate the removal of filter cakes from the filter plates after the filtration process. However, it can indirectly affect the pre-treatment or conditioning of the feed material in certain situations. Here’s how:

- Cake Discharge Efficiency: Efficient cake discharge is crucial for maintaining the performance of the filter press and ensuring continuous operation. If the filter cakes are not effectively discharged from the filter plates, they can build up and impede the filtration process. By breaking up and dislodging the filter cakes, the cake breaker helps prevent blockages and ensures smooth operation.

- Enhanced Filtrate Collection: In some cases, pre-treatment or conditioning of the feed material may result in the formation of filter cakes with cohesive or sticky properties. These cakes may adhere more strongly to the filter plates, making it difficult to remove them during cake discharge. The cake breaker can help break up these cohesive cakes, facilitating their removal and improving the efficiency of filtrate collection.

- Reduced Cleaning Requirements: Effective pre-treatment or conditioning of the feed material can help minimize the accumulation of debris or residues on the filter plates during filtration. By breaking up the filter cakes during cake discharge, what is a cake breaker the cake breaker can further reduce the need for manual cleaning or maintenance of the filter plates, saving time and labor.

- Optimized Filtration Performance: Proper pre-treatment or conditioning of the feed material can improve the efficiency of the filtration process by reducing the formation of fine particles or agglomerates that may clog the filter media. The cake breaker complements this by ensuring that any residual particles or solids remaining on the filter plates are dislodged and removed, maintaining optimal filtration performance.

- Consistency in Operation: Consistent pre-treatment or conditioning of the feed material helps maintain uniformity in the characteristics of the filter cakes formed during filtration. This, in turn, facilitates more consistent and predictable operation of the cake breaker, ensuring reliable cake discharge and minimizing the risk of operational disruptions.

Overall, while the primary function of the cake breaker is to assist in the discharge of filter cakes from the filter plates, its operation can be influenced by the pre-treatment or conditioning of the feed material. By complementing effective pre-treatment practices, the cake breaker helps optimize the performance and efficiency of the filtration process in filter presses.

what is a cake breaker?

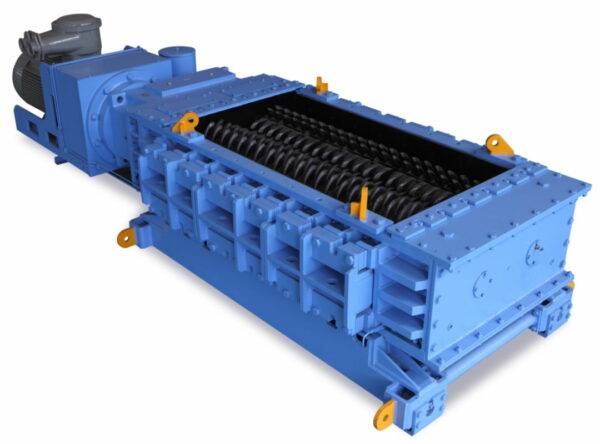

The cake breaker typically consists of one or more devices that mechanically dislodge and break up the filter cakes, allowing them to be easily released from the filter plates. These devices may include:

- Blades or Scraper Bars: Blades or scraper bars are commonly used in cake breakers to physically scrape or shear the filter cakes from the surface of the filter plates. They are often mounted on a moving carriage or frame that traverses the surface of the filter plates to ensure comprehensive cake removal.

- Pneumatic or Hydraulic Pistons: Some cake breakers utilize pneumatic or hydraulic pistons to apply force to the filter cakes, cake breaker causing them to crack or break apart. These pistons may operate in a reciprocating or rotating motion to dislodge the cakes from the filter plates.

- Rollers or Brushes: Rollers or brushes may be employed in cake breakers to roll or sweep across the surface of the filter plates, mechanically breaking up and detaching the filter cakes. These devices may be equipped with bristles or ridges to enhance their effectiveness in cake removal.

- Vibrating Mechanisms: Vibrating mechanisms can be integrated into cake breakers to impart vibrational energy to the filter plates, causing the filter cakes to loosen and dislodge. Vibrating cake breakers are particularly effective for handling cohesive or sticky filter cakes.

- Automatic Control Systems: Some advanced cake breakers feature automatic control systems that regulate the operation of the cake-breaking devices based on feedback from sensors or monitoring systems. These systems ensure optimal cake removal efficiency while minimizing energy consumption and equipment wear.

Overall, the cake breaker is a critical component of filter presses, helping to ensure efficient and reliable cake discharge during solid-liquid separation processes. By mechanically breaking up and dislodging the filter cakes from the filter plates, the cake breaker facilitates the collection of filtrate and prepares the filter press for the next filtration cycle.