This article explores the features and benefits of using standard rectangular steel tube sizes, including their strength and versatility. Learn about the various sizes available and how they are used in construction, manufacturing, and other industries. Gain insights into the benefits of standard sizes for compatibility and cost-efficiency.

Understanding the Features and Benefits of Standard Rectangular Steel Tube Sizes

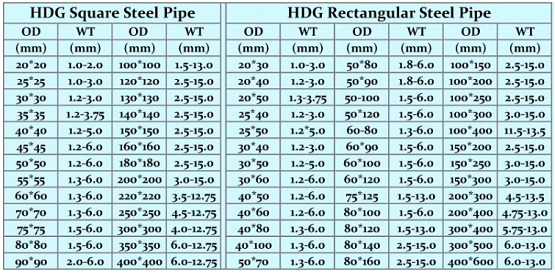

Standard rectangular steel tubes offer strength, durability, and versatility for a wide range of applications. These tubes are available in various sizes, allowing for compatibility and ease of use in construction, manufacturing, and other industries. The benefits of using standard rectangular steel tubes include their high load-bearing capacity, resistance to corrosion, and cost-effectiveness.

Applications of Standard Rectangular Steel Tube Sizes

- Construction: Standard rectangular steel tubes are commonly used in construction for structural support, frames, and fabrication of buildings, bridges, and infrastructure. Their strength and versatility make them ideal for withstanding heavy loads and providing stability.

- Manufacturing: In manufacturing industries, standard rectangular steel tubes are used for fabricating equipment, machinery, and storage systems. They offer a reliable and durable solution for creating strong and stable structures.

Benefits of Standard Sizes for Compatibility and Cost-Efficiency

- Compatibility: Standard rectangular steel tube sizes ensure compatibility with industry standards and commonly used connectors, fittings, and accessories. This allows for easier integration and assembly, saving time and effort during construction or manufacturing processes.

- Cost-Efficiency: Standard sizes are readily available and mass-produced, resulting in cost savings compared to custom-sized tubes. The availability of standard sizes also simplifies procurement and reduces lead times for projects.

Example Applications:

For example, in the construction industry, standard rectangular steel tubes are commonly used for structural support in buildings. These tubes provide the necessary strength and stability to withstand heavy loads, ensuring the safety and durability of the structure.

In the manufacturing sector, standard rectangular steel tubes are utilized for fabricating equipment frames. The standardized sizes allow for easy integration with other components, saving time and reducing costs during the manufacturing process.

Conclusion:

Standard rectangular steel tube sizes offer strength, versatility, and cost-efficiency for various applications in construction, manufacturing, and other industries. Their compatibility with industry standards and readily available sizes make them a reliable choice for projects of all scales.

By utilizing standard sizes, you can ensure compatibility, streamline procurement, and optimize cost-effectiveness. Unlock the potential of standard rectangular steel tube sizes to enhance the strength, stability, and durability of your construction and manufacturing projects.