Steel fiber is a popular material used in construction to reinforce concrete structures. The manufacturing process involves several steps, including the selection of raw materials, melting, casting, and drawing. This article provides a comprehensive guide to the steel fiber manufacturing process, including the different types of steel fibers, their properties, and how they are produced. By the end of this article, you will have a better understanding of the process and how it can be used in construction.

Introduction:

Steel fiber is a type of reinforcement material that is commonly used in construction to enhance the durability and strength of concrete structures. Steel fibers are made by melting steel and then drawing it into thin strands. The fibers are then cut to the desired length and mixed with concrete to create a composite material that is stronger and more durable than traditional concrete. In this article, we will explore the steel fiber manufacturing process in detail, including the raw materials used, the different types of steel fibers, and the production process.

Types of Steel Fibers:

There are several types of steel fibers used in construction, including hooked-end fibers, crimped fibers, and straight fibers. Hooked-end fibers are the most commonly used type of steel fiber and are known for their high bonding strength with concrete. Crimped fibers have a zig-zag shape that helps to improve their bonding strength with concrete. Straight fibers are the simplest type of steel fiber and are used in applications where high bonding strength is not required.

Raw Materials:

The raw materials used in the steel fiber manufacturing process are typically low-carbon steel or stainless steel. Low-carbon steel is the most commonly used material, as it is cost-effective and provides good strength and durability. Stainless steel is used in applications where corrosion resistance is a concern.

Melting:

The first step in the process is the melting of the raw materials. The steel is melted in a furnace at high temperatures, typically between 1600°C and 1800°C. Once the steel has melted, it is poured into a casting machine.

Casting:

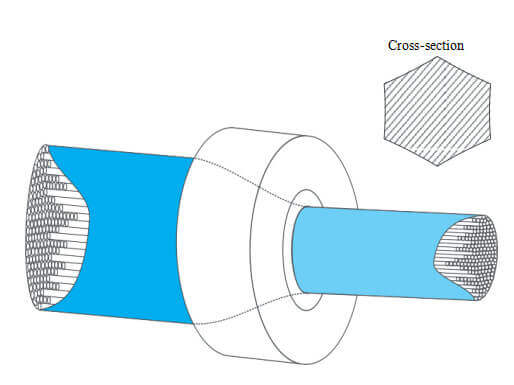

The casting machine is used to form the steel into a thin strand. The steel is poured into a mold, which is then cooled to form a solid strand. The strand is then fed through a drawing machine.

Drawing:

The drawing machine is used to stretch the steel strand into a thinner and longer strand. The steel strand is drawn through a series of dies, which progressively reduce its diameter. The final diameter of the steel fiber is determined by the size of the last die in the drawing process.

Cutting:

Once the steel fiber has been drawn to the desired diameter, it is cut to the desired length. The length of the steel fiber depends on the application and can range from a few millimeters to several centimeters.

Packaging and Shipping:

The final step in the steel fiber manufacturing process is the packaging and shipping of the steel fibers. The steel fibers are typically packaged in bags or boxes and shipped to construction sites or distributors.

Conclusion:

Steel fiber is a popular material used in construction to reinforce concrete structures. The manufacturing process involves several steps, including the selection of raw materials, melting, casting, drawing, cutting, packaging, and shipping. By understanding the steel fiber manufacturing process, you can make informed decisions about the type of steel fiber to use in your construction projects. Whether you are reinforcing a bridge, a tunnel, or a building, steel fiber can help to improve the durability and strength of your concrete structures.